WHAT ARE TYPES OF PIPES USED IN OIL AND GAS INDUSTRIES?

WHAT ARE TYPES OF PIPES USED IN OIL AND GAS INDUSTRIES?

Pipelines used in the oil and gas industry are exceptional, dependent upon various factors, as thing to be dispatched, the transport stage and whether it’s a bit of the upstream, midstream or downstream territory of application. The system of channels that passes on oil and gas in the country over and around the world is, consequently noteworthy. Parts, for instance, channeling materials, should last and withstand solidified conditions, so backing and fixes don’t prevent the supply of the thing.

As indicated by inside and outside piping issues, for instance, utilization, warmth, and weight, assurance of right material for channels and pipe supports improve things altogether. Coming up next are two or three the most broadly perceived sorts of materials that find their use in the oil and gas industry.

Products

Experience

DUPLEX STEEL & ENGINEERING Co. Pvt. Ltd. is a force to reckon with in the field of Importing, Exporting, Stockholding & supplying of Stainless Steel, Duplex Steel, Carbon Steel & High Nickel Alloys in all Shapes of Sheets, Plates, Pipes, Round Bar, Pipe Fittings, Flanges, etc. We are a leading company in sales of ready-at-stock of Stainless Steel & Duplex Steel plates and Pipes.

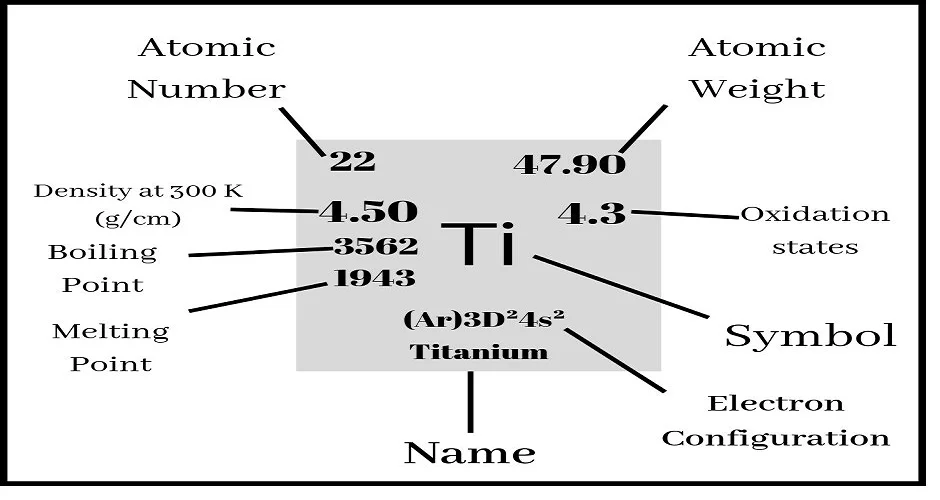

It is understood that when steel is used with various materials, the completed outcome made is an improved composite. For example, when it is mixed with carbon, molybdenum, or nickel, steel invigorates and indicates more prominent resistibility to utilization. From time to time,steel alloys moreover contain chromium. Not withstanding the way that it adds to the nature of steel produces the check ability to fight the effects of carbon dioxide and hydrogen sulfide, and high temperatures. Titanium is a noticeable added substance because of its quality and durability. It is in like manner impenetrable to a collection of substances, including seawater.

It is the most regarded material to be used in the oil and gas industry due to its quality, price, availability and constancy. It is seen that every segment of oil and gas age, running from gathering and refining of things to transportation them over the world, uses it. Steel is exceptionally considered for scattering reason. It is the central material which is used for piping and external parts due to its incredible quality and resistibility to wear. Every so often, when steel is mixed with somewhat level of various materials, it improves the completed outcomes quality, or other appealing characteristics.

Copper and copper mixes are used for explicit purposes, inside oil and gas undertakings. These materials are consistently finding their usage in valves and seals. This is a direct result of properties like electrical and warm conductivity that help to move warmth and cold without contorting, breaking, or slumping for the most part. PE and HDPE channels have been used in the oil and gas examination industry for quite a while. HDPE pipe finds its usage in franking for social occasion and transportation of hydrocarbons, similarly as the transportation and aggregation of water used in this technique.

High-density polyethylene (HDPE) pipe is used as a money saving decision as compared to steel pipe. DUPLEX STEEL & ENGINEERING has led the formation of High-Density Polyethylene Piping systems of higher separation crosswise over (up to 630mm). These channels are most proper for consumable water supply, compound transportation, mechanical spouting exchange and submarine applications.

BENEFITS OF HDPE

- Can be used rather than expensive metal channels

- Potable water supply

- Farm water framework (for tubewell channels)

- Chemical transportation

- Gas Distribution

- C-regard: 150

- Colour: Black

- Range

- In 20mm to 710mmpressure rating: 2.5, 4, 8, 10, 12.5, 16 kg/cm2

FEATURES OF HDPE

- Long persevering

- High Flow Capacity

- Light in weight

- Being adaptable, PE channels require less fittings when stood out from various fittings

- Connection available even outside the channel Points of interest

PE PIPE

PE pipe can withstand unforgiving creation conditions. PE pipe is scratched spot safe and is appropriate for the solids condition in mining purposes. PE pipe is semi-rigid to withstand high external weights. Its versatile nature reaches out with weight floods that construct the life of the pipeline. PE pipe foundations offer whole deal cost advantage because of its physical properties, discharge free joints and constrained help cost. The organization life for PE pipe is assessed to be 50-100 years. The “reasonable water spillage” is zero instead of the customary spillage rates of 10% to 20% for PVC and Ductile Iron. Lightweight PE is viably presented without taking the help of really troublesome work equipment. Trade foundation procedures (Horizontal Directional Drilling, Pipe Bursting, Slip-covering, Plow and Plant, Submerged or Floating Pipe, etc.) can put aside critical time and money in numerous applications.

PACKING

We DUPLEX STEEL & ENGINEERING Ensure the best quality of Packing, because its play important role especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put extraordinary concern regarding packaging.

We pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as:–

- Boxes and Crates

- Shrink-wrapped

- Carton boxes

- Wooden pallets

- Wooden boxes

- Wooden crates