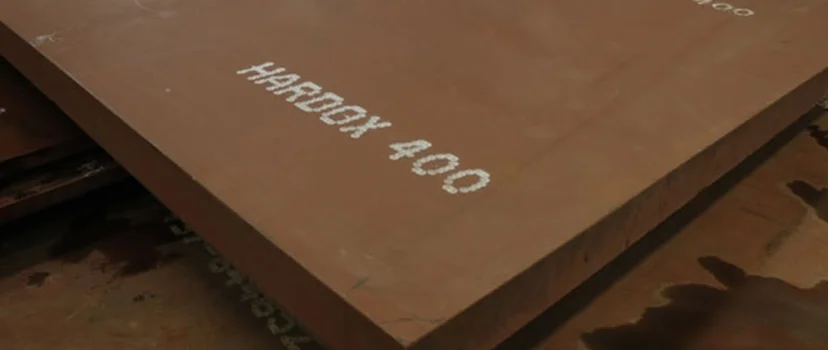

HARDOX 400/500 PLATE

Hardox 400 Plates With its unparalleled blend of hardness and durability, wear plate sets the standard worldwide for scraped area safe (AR) steel. On account of its extraordinary characteristics, it can even execute as a heap bearing part in numerous applications, opening new potential outcomes for auxiliary plan advancement.

Grating applications and forceful wear conditions are basically no counterpart for Hardox. Whatever your wear difficulties, Hardox wear plate offers better wear obstruction, higher payload and longer administration life. The Hardox family includes the first wear plate more slender and thicker than any time in recent memory at 0.7‑160 mm just as cylinders and round bars.

DUPLEX STEEL & ENGINEERING are busy with providing quality shown extent of Abrex 400 Sheets and Sheets which is an all around wear safe plate. Inferable from its high flexibility, the Hardox 400/500 Plates and Sheets can similarly be used for weight bearing commitments as a piece of explicit applications. The upside of using this kind of scratched region safe steel is that the plant, equipment or advancements working life can be enhanced altogether. Moreover, it furthermore upgrades the trustworthiness, robustness and security of structures and apparatus

Hardox 400/500 Plates and Sheets/AR Hardox 400 Equivalent Steel Plates and Sheets are used to make of different things, for instance, transports, chutes and liners and complete holders. Our strong association with reliable shippers enables us to offer these plates as demonstrated by judgments set around our gainful clients. These Hardox 400/500 Plates and Sheets are comprehensively asked for by clients inferable from its top notch, durable execution and harsh advancement Apart from this, these Hardox 400/500 Plates and Sheets demonstrate an incredible blend of high impenetrability to impact, functionality, weld limit and impenetrability to scratched territory.

Hardox 500 Plates and Sheets is a scratched spot safe steel with an apparent hardness of 400/500 HBW. Hardox 400/500 Plates and Sheets is an all around wear safe steel. By virtue of its high toughness, extraordinary bendability and weldability, this steel can be used as a piece of structures with moderate wear.

Abrasion Resistant Abrex 400 Plate plate we offer amazing, lower cost yet the best administration. Accordingly to that our fare account today is in different nations like Egypt, South America Saudi arabia, Thailand,Kuwait,Kazakhstan, Qatar, Oman, Yemen, UAE, Iran, Turkey, Greece, Singapore, Indonesia, Vietnam, South Africa,,Brazil, India, Australia,

Hardox 400 joins through-hardness and durability with unrivaled flame cutting, encircling, and welding characteristics. With a normal BHN hardness of 360 – 440, this simple to utilize grade permits more extension in framework and assembling for the end customer. Hardox 400/500 Plates and Sheets are sensible for applications that require a respectable dimension of scratched territory opposition, for instance, bucket sections, advancement rigging, and wear plates used as a piece of a combination of business adventures like mining, officer administration and improvement. This thing will last up to multiple times longer than ordinary brilliant assistant plate. Each making plant has its own prohibitive mixture sythesis and heat-treating process. DUPLEX STEEL & ENGINEERING is lively to give the processing plant specific subtleties.

SPECIFICATIONS of HARDOX 400/500 PLATE :

| Item | Abrasion Resistant Plate |

|---|---|

| Material | Hardox 400 |

| Thickness | 0.1mm To 100 mm |

| Width | 500-3000mm |

| Length | 1000-12000mm |

| Heat Treatment | N, Q+T |

| Surface Paint | EP, PE, HDP, SMP, PVDF |

Chemical Composition of HARDOX 400/500 PLATE :

| Plate | C | Si | Mn | P | S | Cr | Ni | Mo | B | CEV | CET |

|---|---|---|---|---|---|---|---|---|---|---|---|

| thickness mm | max % | max % | max % | max % | max % | max % | max % | max % | max % | typv | typv |

| 3-(8) | 0.15 | 0.7 | 1.6 | 0.025 | 0.01 | 0.3 | 0.25 | 0.25 | 0.004 | 0.33 | 0.23 |

| 08/20/13 | 0.15 | 0.7 | 1.6 | 0.025 | 0.01 | 0.5 | 0.25 | 0.25 | 0.004 | 0.37 | 0.27 |

| (20)-32 | 0.18 | 0.7 | 1.6 | 0.025 | 0.01 | 1 | 0.25 | 0.25 | 0.004 | 0.48 | 0.29 |

| (32)-45 | 0.22 | 0.7 | 1.6 | 0.025 | 0.01 | 1.4 | 0.5 | 0.6 | 0.004 | 0.57 | 0.31 |

| (45)-51 | 0.22 | 0.7 | 1.6 | 0.025 | 0.01 | 1.4 | 0.5 | 0.6 | 0.004 | 0.57 | 0.38 |

| (51)-80 | 0.27 | 0.7 | 1.6 | 0.025 | 0.01 | 1.4 | 1 | 0.6 | 0.004 | 0.65 | 0.41 |

| (80)-130 | 0.32 | 0.7 | 1.6 | 0.025 | 0.01 | 1.4 | 1.5 | 0.6 | 0.004 | 0.73 |

Plate thickness below 4 mm only after special agreement

CEV = C+Mn/6+(Cr+Mo+V)/5+(Cu+Ni)/15

CET = C + (Mn+Mo)/10+( Cr+ Cu)/20+ Ni/40

Mechanical Properties of HARDOX 400/500 PLATE :

| Grade | Mechanical Property | Charpy V Impact Test | |||

|---|---|---|---|---|---|

| HADOX 400 | Yield (Min Mpa) | Tensile (Mpa) | Elongation (Min %) | Degree | longitudinal |

| 1000 | 1250 | 10 | -40 | 45 J | |

Hardox 400/ 450 Plates / Sheets Price - 2023 Updated :

| Hardox 400/ 450 Plate | Price/kg |

|---|---|

| HARDOX 400 PLATE | 180₹ |

| Hardox 550 Plate | 195₹ |

| Abrasion Resistant Hardox Plate | 200₹ |

| Weather Resistant Plate | 160₹ |

| Rectangular Hardox Plate | 180₹ |

Note: Above price list updated as per 2023 (Price will Fluctuate as per Market).

Features Of Hardox 400 Plates & Sheets

- Excellent Cold Bending

- Welding Properties

- Long Wear Life

- Flat Clean

- Shot Blasted

- Primed Finished Products

- High Impact Properties

- Grain-Refined

Testings (Destructive, Non Destructive):

- Positive Material Identification – PMI Testing

- Chemical Analysis – Spectro Analysis

- Mechanical Testing Such as Tensile, Elongation, Reduction of Area

- Micro Test

- Macro Test

- Hardness Test

- Pitting Resistance Test

- Intergranular Corrosion (IGC) Test

- Flaring Test

- Flattening Test

- Hydrostatic Test

- Hydrogen-Induced Cracking (HIC) Test, NACE TM0284

- Sulfide Stress Corrosion Cracking (SSC), NACE TM 0177

- Radiography Test

- Dye Penetrant Test (DP Test)

- Ultra Sonic Test (UT)

- Eddy Current Testing

- Impact Test

- Bend Test

APPLICATION

-

Construction

-

Power Generation Industries

-

Oil and Gas Industry

-

Petrochemical Industries

-

Pulp & Paper Industries

-

Biofuels plant

COUNTRIES WE EXPORT TO

Products

Quotation & Order

Call Us or Mail us For Quotation & Questions Related To Duplex Steel Pipes